Case Study: Solving a Complex Sealing Challenge with Custom Gaskets

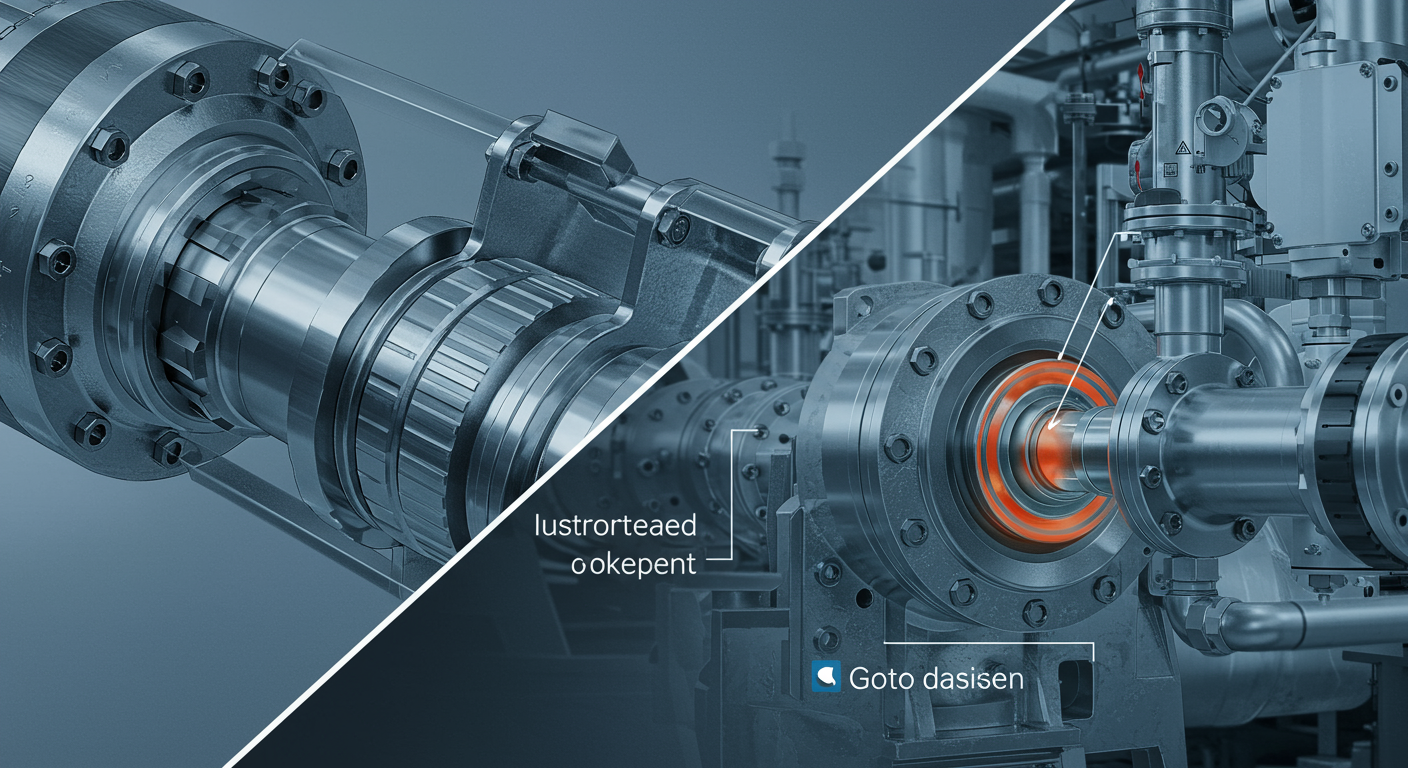

The Problem: Persistent Leaks in a Critical Industrial Application

A major industrial client in Egypt experienced persistent leakage from a crucial component within their manufacturing process. This resulted in significant downtime, production losses, and safety concerns. The existing sealing solution proved inadequate, leading to a constant search for a more reliable and durable alternative. The challenge demanded a bespoke solution capable of withstanding extreme pressure and temperature fluctuations.

Identifying the Root Cause

Our engineering team conducted a thorough site assessment, analyzing the existing system and identifying the root cause of the leakage. This involved meticulous examination of the component's design, material properties, and operational conditions. The analysis revealed that the existing gasket material lacked the necessary resilience and compression set to maintain an effective seal under the extreme operating pressures.

The Vensco Solution: A Custom-Engineered Rubber Gasket

Based on our in-depth analysis, Vensco's engineering team designed and manufactured a custom rubber gasket tailored to the client's specific requirements. This involved:

- Selecting a high-performance rubber compound with exceptional chemical resistance, temperature stability, and compression set resistance.

- Optimizing the gasket's design to ensure a perfect fit and consistent contact pressure across the sealing surface.

- Implementing rigorous quality control measures throughout the manufacturing process to guarantee consistent performance.

Material Selection & Specifications

The chosen rubber compound exhibited superior resistance to the client's specific operating conditions, including high temperatures, aggressive chemicals, and cyclical pressure fluctuations. Key material properties included:

- Tensile Strength: >20 MPa

- Elongation at Break: >300%

- Shore Hardness: 70A

- Temperature Range: -20°C to +120°C

Implementation and Results

The custom-engineered gasket was seamlessly integrated into the client's system. Post-installation monitoring confirmed a complete elimination of the leakage problem. This resulted in:

- Zero downtime: Production continued without interruption.

- Significant cost savings: Eliminated production losses and maintenance expenses associated with the previous leakage issue.

- Improved safety: Resolved a potential safety hazard related to fluid leaks.

The Vensco Advantage

Vensco's success in solving this complex sealing challenge highlights our commitment to providing comprehensive engineering solutions tailored to our client's specific needs. Our deep expertise in material science, coupled with our access to a wide range of high-performance materials and our commitment to local manufacturing in Egypt, makes us the ideal partner for demanding industrial applications. We offer unparalleled technical consultation services to ensure the optimal selection and implementation of sealing solutions for your specific challenges.

Conclusion

This case study demonstrates Vensco's ability to deliver innovative, effective, and cost-efficient solutions to complex engineering challenges. By leveraging our expertise in material selection, design optimization, and precision manufacturing, we helped our client overcome a persistent leakage problem, ensuring operational efficiency, cost savings, and improved safety.

Get a personalized quote for your sealing needs today.