The Thermal Break: How Backer Rods Improve Window Insulation

Understanding Thermal Breaks in Window Construction

Energy efficiency is paramount in modern building design. Heat transfer through windows significantly impacts a building's energy consumption. A thermal break is a crucial element in minimizing this heat transfer, preventing energy loss in winter and heat gain in summer. This is achieved by interrupting the conductive path of heat through the window frame.

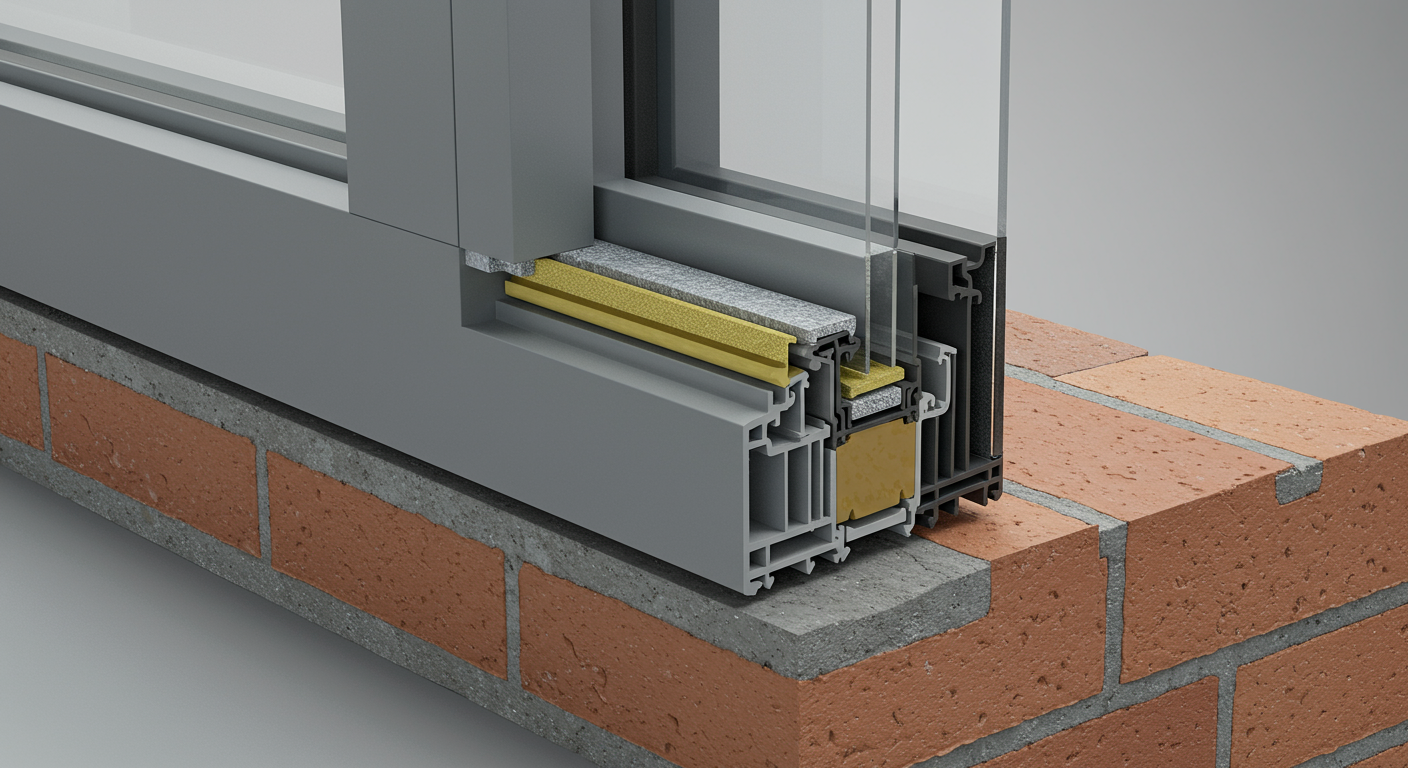

The Role of the Window Frame

Window frames, traditionally made of conductive materials like aluminum, can act as a pathway for heat to move between the inside and outside environments. This conductive heat transfer reduces the effectiveness of the window's insulating glass units.

Backer Rods: Creating an Effective Thermal Break

Backer rods, typically made from closed-cell polyethylene foam, are a simple yet highly effective solution for creating a thermal break. These cylindrical foam inserts are placed within the window frame's cavity before the sealant is applied.

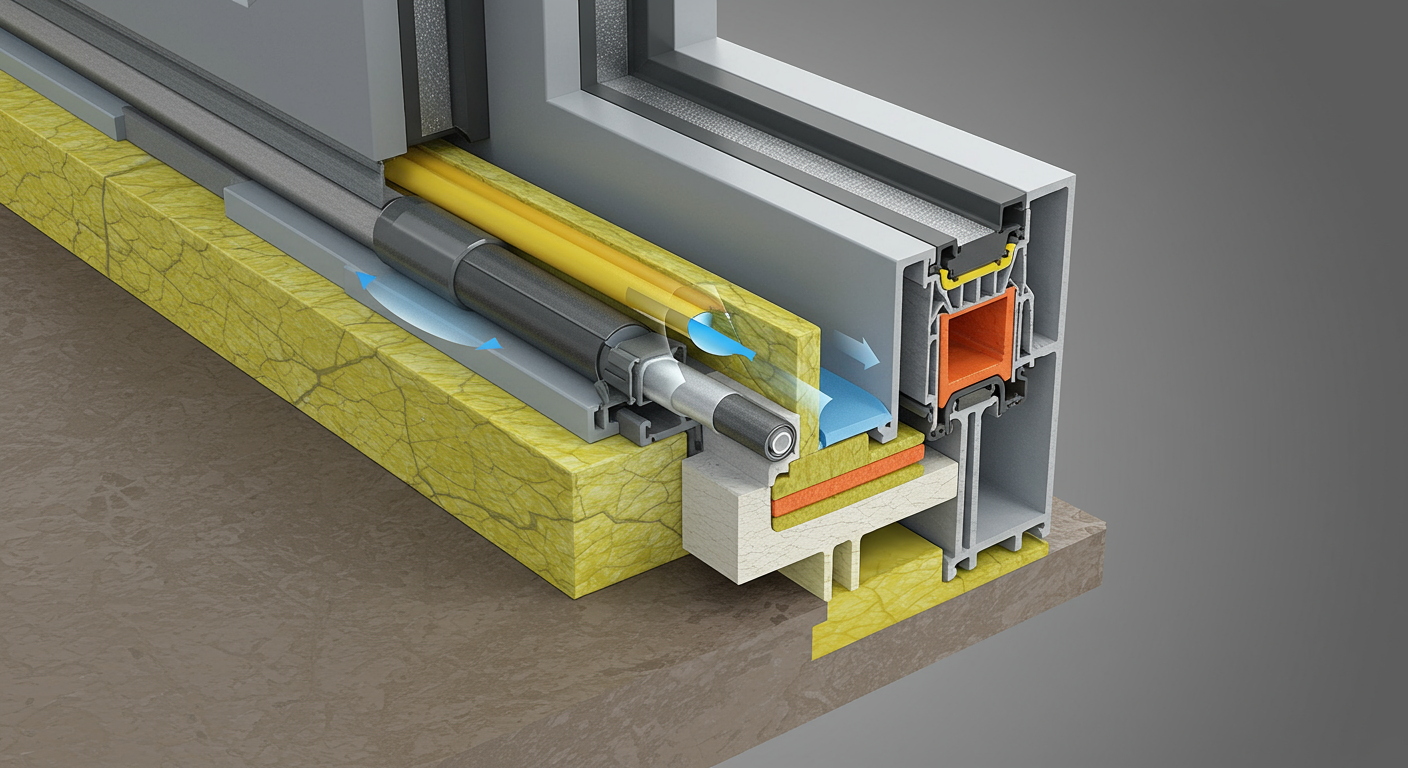

How Backer Rods Work

By filling the gaps and irregularities within the window frame, backer rods prevent the sealant from bridging across the conductive material of the frame. This creates an air gap, significantly reducing the conductive heat transfer. The closed-cell structure of the polyethylene foam also minimizes the convective and radiative heat transfer.

- Reduced Heat Transfer: The air gap created by the backer rod significantly reduces the flow of heat through the window frame.

- Improved Insulation: This leads to better overall window insulation, reducing energy costs and improving comfort.

- Enhanced Sealant Performance: Backer rods help ensure a proper seal, preventing air and water infiltration.

Choosing the Right Backer Rod: Material Considerations

The selection of the appropriate backer rod depends on several factors, including the size of the gap, the required level of insulation, and the environmental conditions. Polyethylene foam is a popular choice due to its excellent thermal performance and resistance to moisture. EVA foam also presents a viable option, offering varied levels of density and compressibility, according to specific application needs.

The Vensco Advantage

Vensco Engineering Trading & Supplies offers a wide range of high-quality backer rods, expertly selected to meet the diverse requirements of the Egyptian construction industry. We provide comprehensive technical support, ensuring you choose the right product for your specific application. Our commitment to local sourcing and our team of expert engineers guarantee a reliable and efficient service, from material selection to on-site support. We offer a diverse inventory of closed-cell foam materials, all made to the highest quality standards, ensuring optimal performance and longevity. Contact us today to discuss your project needs.

Conclusion

Implementing a thermal break using backer rods is a simple yet highly effective way to improve the energy efficiency of windows. By reducing heat transfer, backer rods contribute to energy savings, increased comfort, and reduced environmental impact. Choose high-quality materials like those supplied by Vensco to ensure optimal performance and long-term reliability.

Get a personalized quote for your insulation needs today!