Polyethylene Foam: The Unsung Hero of Packaging and Insulation

Understanding Polyethylene Foam: Properties and Applications

Polyethylene foam, a versatile closed-cell material, offers exceptional performance in diverse applications. Its low density, coupled with high strength, makes it ideal for cushioning and impact absorption. Furthermore, its closed-cell structure provides excellent thermal insulation and water resistance. This makes polyethylene foam a cost-effective solution for a wide array of industrial and commercial needs.

Key Properties of Polyethylene Foam:

- Excellent thermal insulation: Polyethylene foam boasts a high R-value, indicating its effectiveness in reducing heat transfer. This makes it a popular choice for building insulation and HVAC systems.

- Superior sound absorption: Its closed-cell structure contributes to significant noise reduction. This is crucial in applications requiring acoustic dampening.

- Lightweight and easy to handle: The low density of polyethylene foam simplifies installation and transportation, reducing labor costs.

- Durable and long-lasting: Resistant to moisture, chemicals, and degradation, polyethylene foam provides consistent performance over extended periods.

- Versatile shaping and customization: It can be easily molded or cut into various shapes and sizes, catering to specific application requirements.

Polyethylene Foam in Construction and Beyond

Polyethylene foam finds extensive use in various sectors. Its exceptional properties make it a preferred material for:

Construction Applications:

- Thermal insulation for walls and roofs: Reducing energy consumption and improving building efficiency.

- Acoustic insulation for noise control: Minimizing noise pollution in residential and commercial buildings.

- Underlayment for flooring: Providing thermal and acoustic insulation while improving comfort.

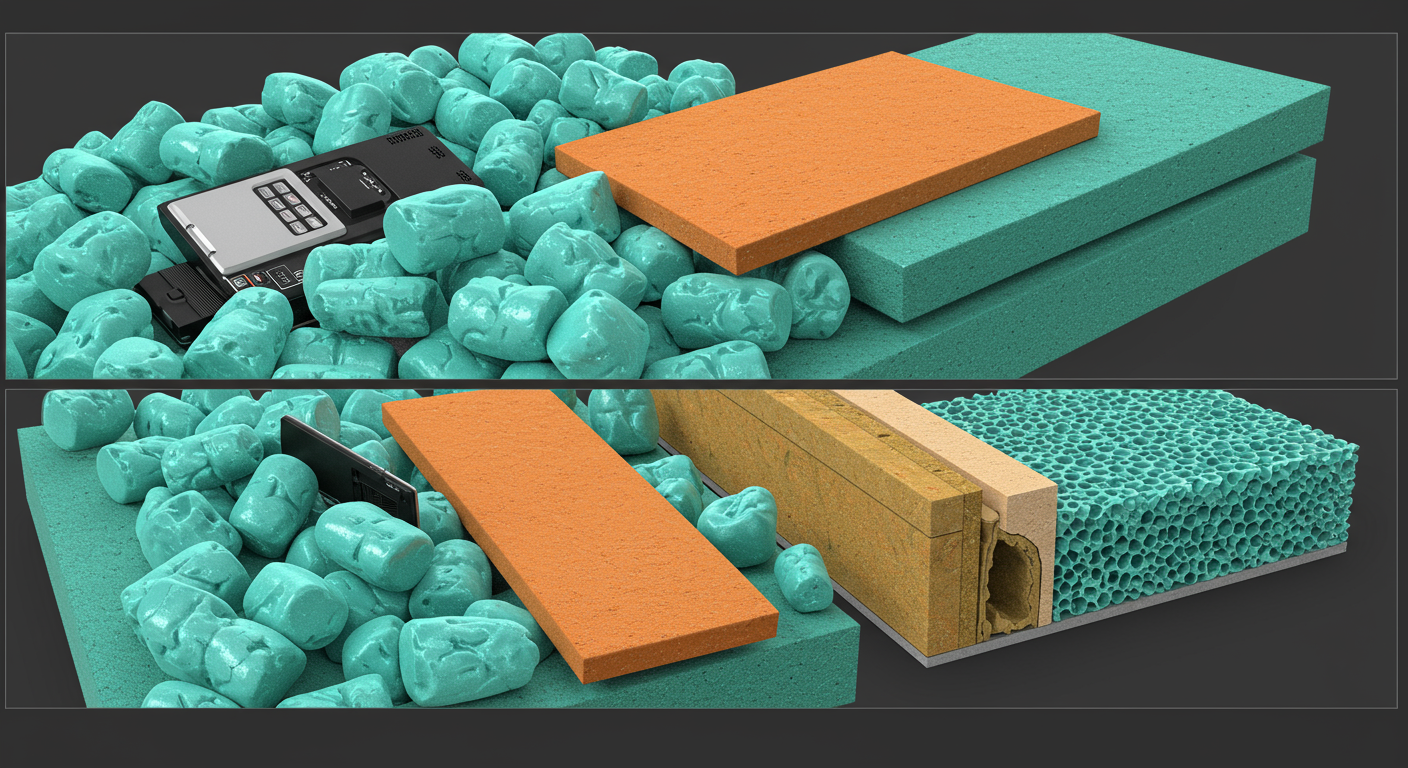

Packaging and Protection:

- Cushioning fragile goods during shipping: Preventing damage and ensuring product integrity.

- Protective packaging for electronic components: Safeguarding sensitive equipment from shock and vibration.

Other Applications:

- Automotive NVH (noise, vibration, and harshness) control: Enhancing the driving experience and reducing interior noise.

- HVAC system insulation: Improving energy efficiency and reducing operational costs.

The Vensco Advantage

Vensco Engineering Trading & Supplies offers high-quality polyethylene foam sourced from reputable manufacturers. We are committed to providing superior products and unparalleled technical support to our clients. Our experienced team of engineers provides comprehensive technical consultation, ensuring you select the optimal polyethylene foam solution for your specific needs. Choose Vensco for reliable locally sourced products, expert advice, and a dedicated commitment to your project success.

Conclusion

Polyethylene foam stands as a remarkably versatile material, delivering exceptional performance in thermal insulation, acoustic dampening, and protective packaging. Its unique properties and cost-effectiveness make it an ideal choice for diverse applications across numerous industries. Contact our technical consultation team to discuss your specific project requirements and discover how Vensco can help you engineer the right solution.

Get a personalized quote for your insulation needs today.