The Art of Joint Sealing: Tips and Tricks for a Perfect Finish

Understanding the Importance of Proper Joint Sealing

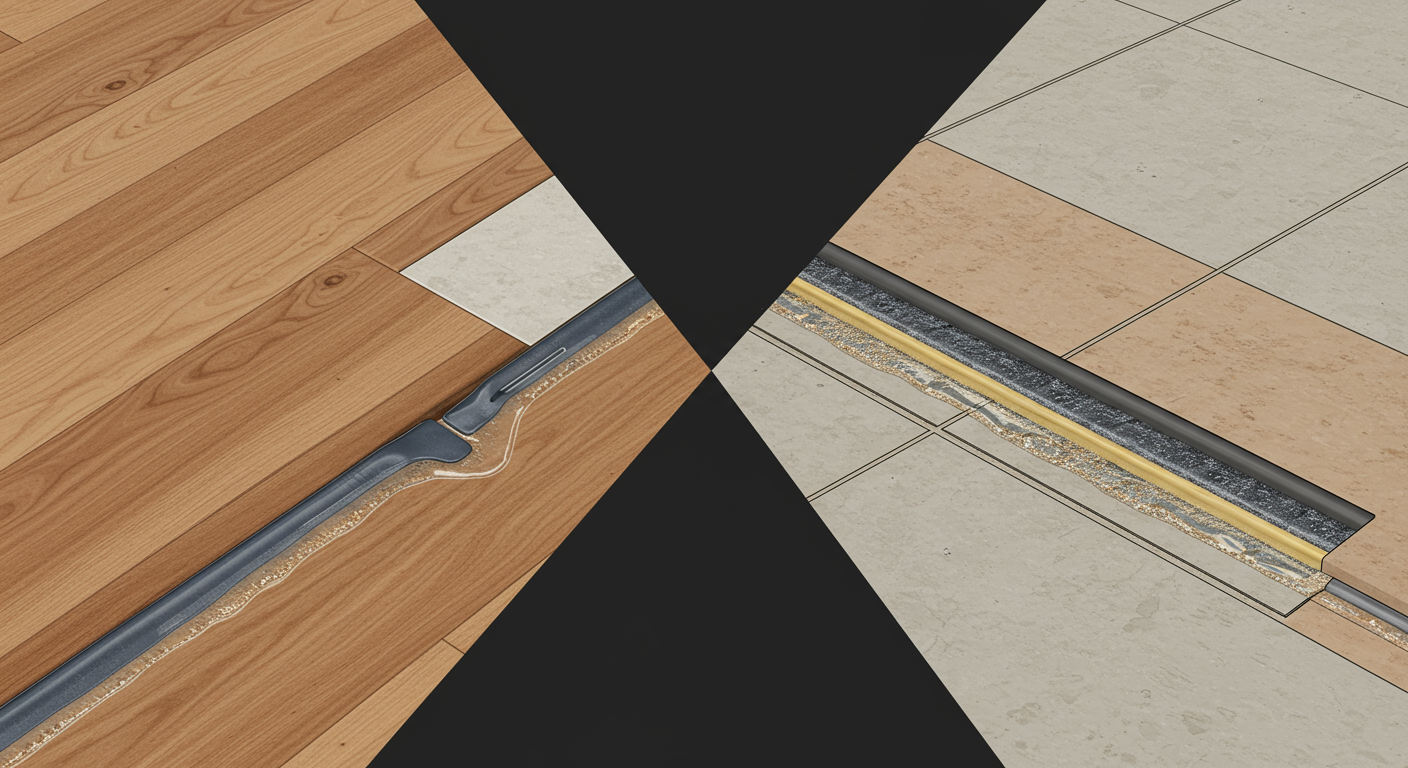

Effective joint sealing is crucial in various applications, from construction and automotive manufacturing to HVAC systems. Poorly sealed joints can lead to significant problems, including:

- Heat loss: Compromising energy efficiency and increasing operational costs.

- Noise transfer: Reducing sound insulation and creating disruptive environments.

- Water ingress: Causing damage to structures and components.

- Vibration transmission: Leading to equipment malfunction and structural fatigue.

Choosing the Right Sealing Material

The selection of sealing material depends on the specific application and its environmental demands. Key factors to consider include:

- Thermal conductivity: For heat insulation, materials with low thermal conductivity are essential, such as closed-cell polyethylene foam.

- Acoustic properties: The sound absorption coefficient is critical for noise reduction applications. EVA foam and other specialized foams are effective acoustic insulation materials.

- Chemical resistance: The material must be compatible with the surrounding environment and resist degradation from chemicals or moisture.

- Durability and longevity: A high-quality seal should withstand stress, temperature fluctuations, and aging.

Understanding EVA and Polyethylene Foam Properties

EVA foam and polyethylene foam are popular choices for joint sealing, each with unique properties. Polyethylene foam, particularly closed-cell polyethylene foam, offers excellent thermal insulation due to its low thermal conductivity. EVA foam excels in sound absorption and is often preferred for acoustic applications. Consult the technical data sheet for detailed EVA foam specifications and polyethylene foam R-value information.

Best Practices for Joint Sealing

Achieving a professional-grade seal requires attention to detail and proper technique. Follow these steps for optimal results:

- Clean the surfaces: Thoroughly clean the surfaces to be sealed, removing any dust, debris, or existing sealant.

- Apply a primer (if necessary): Certain materials may benefit from a primer to improve adhesion.

- Apply the sealant evenly: Ensure consistent coverage without gaps or voids.

- Allow sufficient curing time: Follow the manufacturer's instructions regarding curing time before exposing the joint to stress or environmental conditions.

- Inspect the finished seal: Check for any imperfections and address them immediately.

Common Pitfalls to Avoid

Several common mistakes can compromise the effectiveness of joint sealing:

- Using the wrong material: Selecting a material unsuitable for the application's requirements.

- Inadequate surface preparation: Poor cleaning or primer application can lead to poor adhesion.

- Uneven sealant application: Gaps or voids weaken the seal and reduce its effectiveness.

- Ignoring curing time: Premature stress on the joint can lead to failure.

The Vensco Advantage

Vensco Engineering Trading & Supplies offers a wide range of high-quality sealing materials, including EVA foam and polyethylene foam, manufactured to exacting standards. We are committed to providing technical expertise and support to our clients, ensuring the right solution is selected for each unique application. Our local presence in Egypt guarantees prompt delivery and responsive service. Contact our technical consultation team to discuss your specific requirements.

Conclusion

Mastering the art of joint sealing is crucial for ensuring the success of numerous projects. By understanding material properties, employing best practices, and avoiding common pitfalls, you can achieve professional-grade results. Contact Vensco today to discover how our expertise and high-quality products can help you achieve perfect joint seals every time.

Get a personalized quote for your insulation needs today.