The Importance of High-Quality Sealing Materials in Water Management Projects

Introduction: Preventing Leaks and Ensuring Efficiency in Water Management

Water management projects, encompassing both water supply and wastewater treatment, demand meticulous attention to detail. Leaks and inefficiencies can lead to significant water loss, environmental damage, and financial repercussions. High-quality sealing materials play a crucial role in mitigating these risks by ensuring the integrity and longevity of the systems involved.

The Critical Role of Sealing Materials

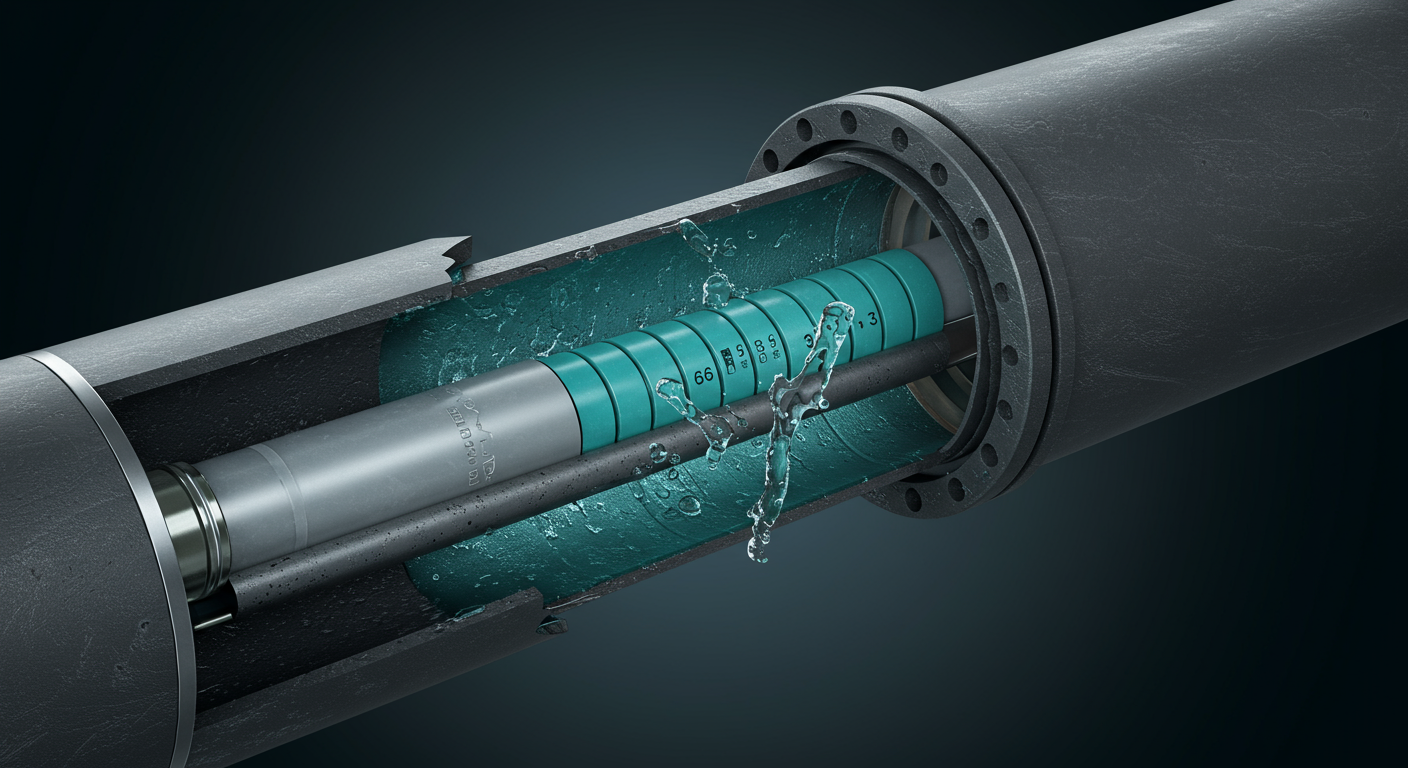

Preventing Leaks and Water Loss

Reliable sealing is paramount in preventing leaks throughout the entire water management infrastructure. From pipelines and reservoirs to treatment plants and pumping stations, effective sealing materials prevent water loss, maintain system pressure, and minimize environmental impact. Leaks can lead to costly repairs, disruptions in service, and potential contamination.

Enhancing System Efficiency

Beyond leak prevention, proper sealing contributes to increased system efficiency. Well-sealed joints and connections minimize pressure loss, optimizing the performance of pumps and other components. This translates to lower energy consumption and reduced operational costs.

Protecting Infrastructure Longevity

High-quality sealing materials are designed to withstand the harsh conditions often encountered in water management systems, including exposure to water, chemicals, and extreme temperatures. This resistance to degradation prolongs the lifespan of the infrastructure, minimizing the need for frequent repairs and replacements.

Choosing the Right Sealing Material: Key Considerations

The selection of sealing materials depends on several factors, including the specific application, the type of fluid being handled, and the environmental conditions. Key properties to consider include:

- Chemical Resistance: The material must be resistant to the chemicals present in the water or wastewater being managed.

- Temperature Range: The material needs to withstand the temperature fluctuations within the system.

- Pressure Tolerance: The material must be able to withstand the operating pressure of the system.

- Durability: The material should exhibit long-term stability and resistance to degradation.

Polyethylene foam and EVA foam, offered by Vensco, are excellent examples of materials that frequently meet these demanding criteria. Their properties offer a balance of performance and cost effectiveness.

Case Study: A Successful Water Management Project with Vensco

Vensco recently supplied high-performance sealing materials for a large-scale wastewater treatment plant in Egypt. The project required materials capable of withstanding harsh chemicals and fluctuating temperatures. Our closed-cell foam solutions proved ideal, successfully preventing leaks and contributing to the overall efficiency and longevity of the system.

The Vensco Advantage: Your Partner in Water Management Success

Vensco Engineering Trading & Supplies offers a wide range of high-quality sealing materials tailored to the specific needs of water management projects. We provide expert technical consultation, ensuring you select the optimal materials for your application. Our deep product specialization and local Egyptian presence guarantee reliable supply and efficient project support. We understand the challenges of water management and are committed to providing you with the solutions you need to succeed.

Conclusion: Investing in Quality Sealing for Long-Term Success

Investing in high-quality sealing materials is not merely a cost, but a strategic decision that protects your investment, enhances operational efficiency, and minimizes environmental impact. Vensco's commitment to quality and technical expertise makes us the ideal partner for your water management projects.

Contact our technical consultation team to discuss your specific project requirements.