The Surprising Uses of Polyethylene Foam in the Automotive Industry

Enhancing Automotive Performance with Polyethylene Foam

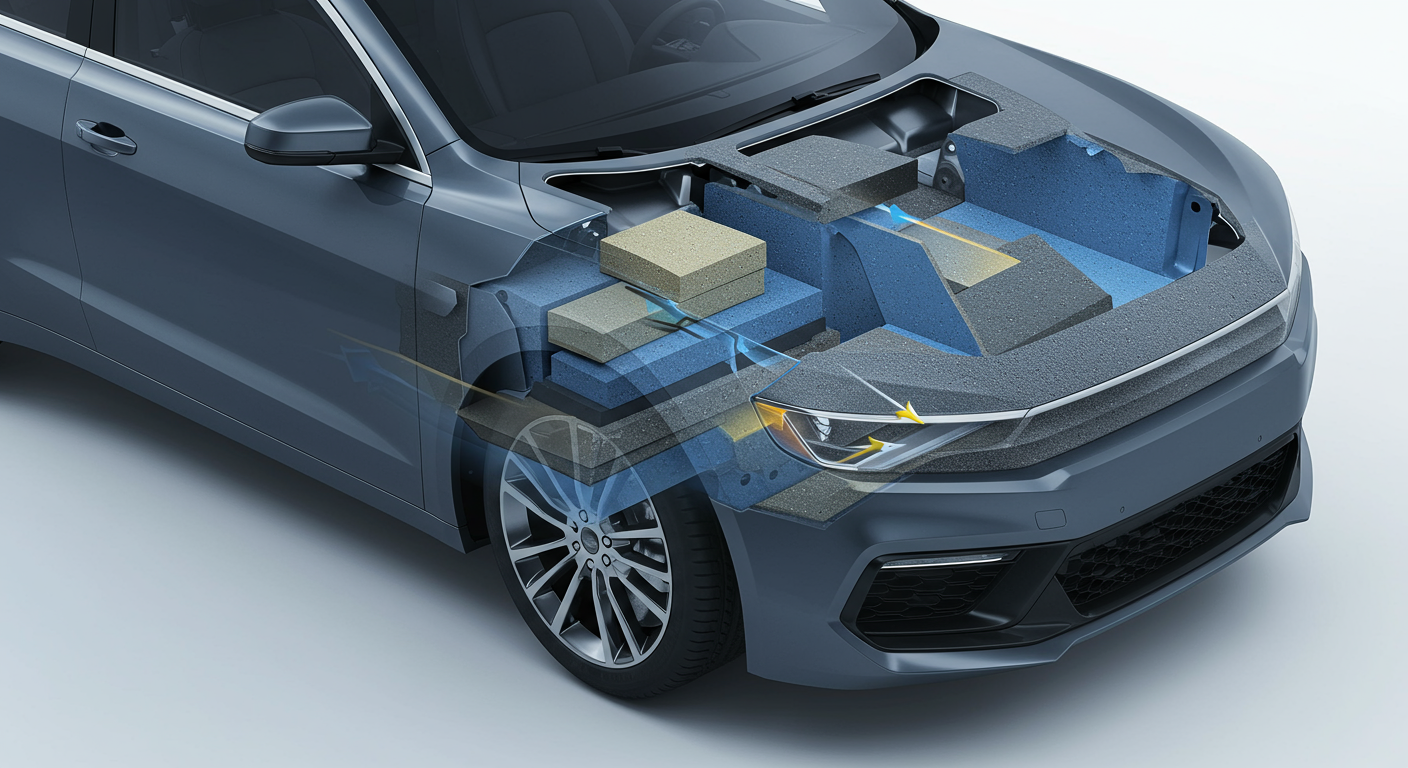

Polyethylene foam, a versatile and lightweight material, plays a crucial, often unseen, role in modern vehicle design and manufacturing. Its unique properties make it an ideal solution for a range of automotive applications, contributing to improved vehicle performance, comfort, and safety. This article explores the surprising versatility of polyethylene foam and its impact on the automotive sector.

Vibration Dampening and Noise Reduction (NVH)

One of the primary uses of polyethylene foam in the automotive industry is noise, vibration, and harshness (NVH) reduction. Its closed-cell structure effectively absorbs and dampens vibrations, reducing unwanted noise transfer within the vehicle's cabin. This translates to a quieter, more refined driving experience for passengers. Polyethylene foam's ability to absorb high-frequency sounds is particularly valuable in reducing engine noise and road noise.

Thermal Insulation and Climate Control

Polyethylene foam's excellent thermal insulation properties make it a valuable component in maintaining a comfortable interior temperature. By preventing heat transfer, it helps reduce the load on the vehicle's air conditioning system, improving fuel efficiency and contributing to a more energy-efficient vehicle. Its use in HVAC systems further enhances climate control performance.

Interior Trim and Components

Beyond its functional roles, polyethylene foam also finds use in creating various interior components. Its lightweight nature and ease of molding make it suitable for creating dashboards, door panels, and other interior trim pieces. The material can be easily customized to meet specific design requirements, offering both functionality and aesthetic appeal. The material's durability and resistance to damage further enhance its suitability for this application.

Protecting Sensitive Components

Polyethylene foam is used as a protective barrier for sensitive electronic components and wiring harnesses. Its cushioning properties help to absorb shocks and vibrations, safeguarding these crucial parts from potential damage during transit and operation. This is particularly important in environments subject to significant vibration or impact.

The Vensco Advantage

Vensco Engineering Trading & Supplies offers a comprehensive range of high-quality polyethylene foams, tailored to meet the specific needs of the automotive industry. Our expert team provides technical consultation services to assist you in selecting the optimal foam for your application, ensuring optimal performance and cost-effectiveness. We are committed to providing locally sourced solutions, supporting Egyptian manufacturing and construction projects. Partner with Vensco for reliable, high-performance polyethylene foam, and benefit from our deep product expertise and unwavering commitment to customer success.

Conclusion

Polyethylene foam's versatility makes it an indispensable material in the automotive industry, impacting vehicle performance in numerous ways. From enhancing noise reduction and thermal insulation to creating interior components, its use demonstrates its valuable contribution to modern vehicle design. Contact our technical consultation team to discuss your specific project requirements and discover how Vensco can help you leverage the benefits of polyethylene foam in your next automotive project.