The Ultimate Guide to Choosing the Right Backer Rod for Your Project

Understanding Backer Rods: The Foundation of Effective Sealing

Backer rods are essential components in various sealing and joint filling applications. They provide a crucial function by creating a consistent, compressible backing for sealants, ensuring proper adhesion and preventing sealant from sinking into joints. This guide will explore the different types of backer rods, their properties, and how to select the ideal one for your specific project needs.

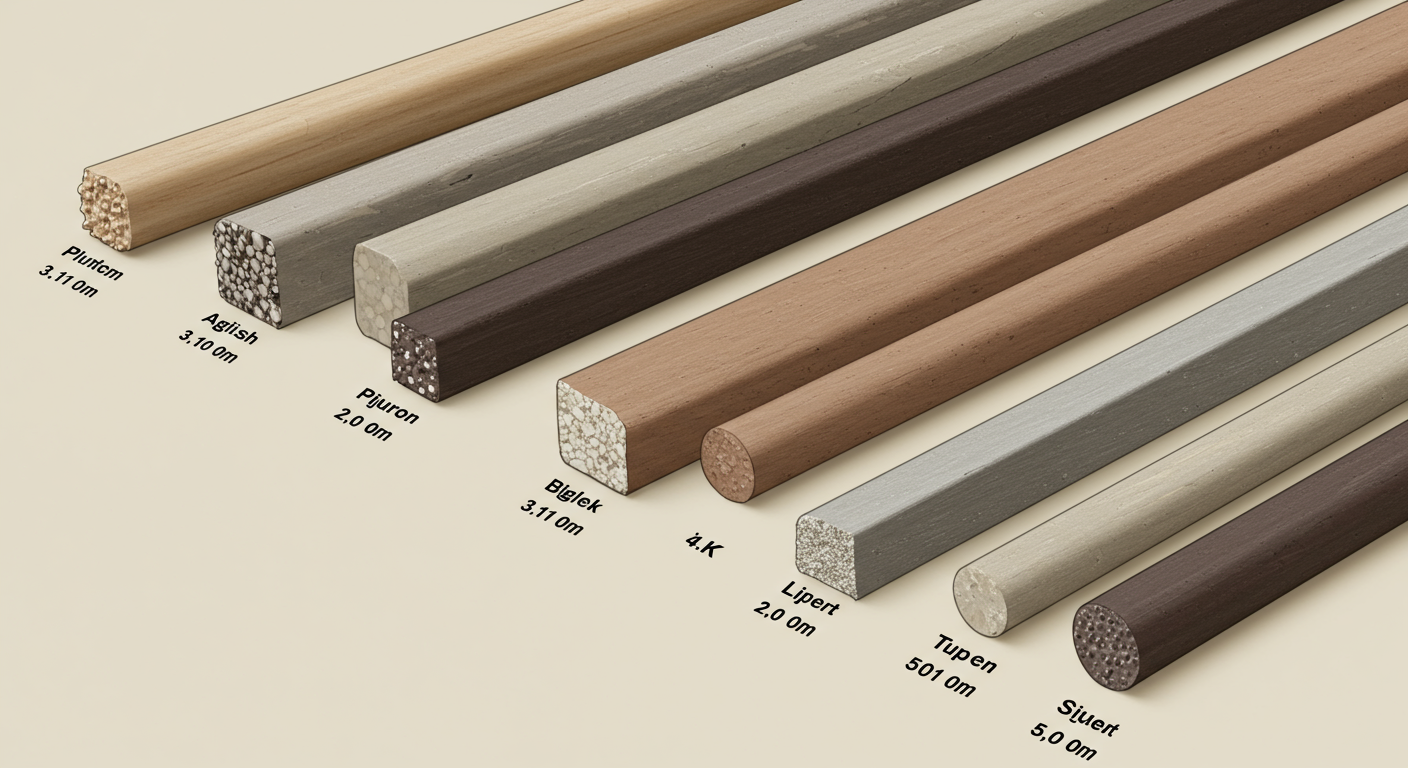

Types of Backer Rods

Several materials are used in the manufacturing of backer rods, each offering unique properties:

- Closed-Cell Polyethylene Foam: This is the most common type, offering excellent flexibility, compressibility, and resistance to moisture and chemicals. Closed-cell structure ensures minimal water absorption, making it ideal for exterior applications. Its low thermal conductivity also contributes to improved insulation.

- Open-Cell Polyethylene Foam: While less commonly used, open-cell foams are more compressible than closed-cell options, making them suitable for irregular joints. However, they are more susceptible to moisture absorption.

- Ethylene Vinyl Acetate (EVA) Foam: EVA foam backer rods offer good flexibility and cushioning properties. They are often used in applications requiring a slightly more resilient and durable seal.

Selecting the Right Backer Rod: Key Considerations

Choosing the right backer rod depends on several factors:

Joint Width & Depth

The diameter of the backer rod should be approximately 1/3 to 1/2 the width of the joint. This ensures proper compression and creates optimal space for the sealant.

Material Compatibility

Consider the compatibility of the backer rod with the sealant being used. Always refer to the sealant manufacturer's guidelines for compatible materials.

Environmental Factors

Outdoor applications require backer rods with excellent resistance to UV degradation, moisture, and temperature fluctuations. Closed-cell polyethylene foam is typically preferred for these scenarios.

Application-Specific Requirements

Different applications have varying demands. For example, acoustic applications might benefit from materials with higher sound absorption coefficients, while thermal insulation projects require backer rods with low thermal conductivity.

The Vensco Advantage: Your Partner in Sealing Solutions

At Vensco Engineering Trading & Supplies, we offer a wide range of high-quality backer rods to meet the diverse needs of our clients. Our commitment to providing locally sourced, superior materials and our team of experienced engineers ensure you receive the perfect solution for your project. We also offer technical consultations to help you navigate the complexities of material selection and application. Choosing Vensco means choosing a reliable partner who understands the intricacies of your project and is committed to delivering superior results. Our commitment to quality and our deep expertise in industrial materials distinguish us as the preferred supplier of high-quality sealing solutions in Egypt.

Conclusion: Ensuring a Perfect Seal, Every Time

Proper backer rod selection is crucial for ensuring the longevity and effectiveness of any sealant application. By considering joint dimensions, material compatibility, environmental factors, and application-specific requirements, you can optimize the performance of your project. Contact our technical consultation team to discuss your specific project requirements and let Vensco help you engineer the perfect solution for your sealing challenges.

Get a personalized quote for your insulation needs today.